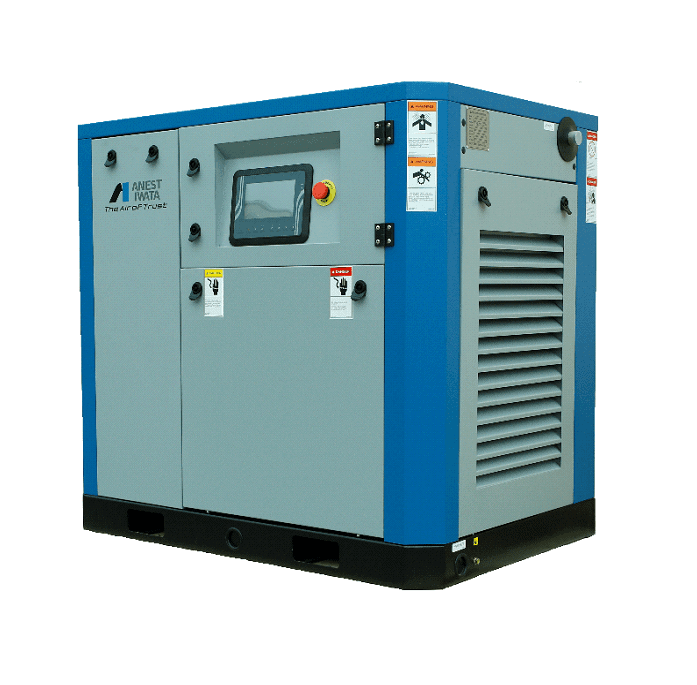

Bimpex is a leading rotary screw air compressors supplier in Mumbai, India, which are crucial equipment in various industrial facilities. These screw air compressors use two helical rotors that push air through the compression chamber, creating a continuous and smooth flow of compressed air. They are efficient, reliable, and commonly used in industrial application. Screw air compressors are also commonly known as Rotary Screw compressors.

Bimpex, a leading rotary screw air compressor distributor in Mumbai, India, offers a range of screw air compressors that deliver compressed air which is often used to power pneumatic tools and have a wide range of other industrial applications. These screw air compressors are ideal for applications that require continuous air flow.

Rotary screw air compressor gets its name because of its basic functioning element are two interlocking helical screws. These helical screws compress the air as it moves through the machine. These air compressors are a most preferred choice in industrial applications because they are very reliable and efficient in delivering continuous compressed air. Rotary screw air compressors offer consistent and high-performance air compression solutions.

The working principle of a rotary screw air compressor involves two intermeshing helical screws that compresses air. As the screws rotate, they reduce the volume of air, generating high-pressure air for various applications. This continuous process of air compression within the screw mechanism ensures a steady and efficient supply of compressed air, ideal for industrial and commercial purposes.

When compared to reciprocating air compressors, the working shows a remarkable difference. Reciprocating air compressors use pistons to compress air in a cylinder unlike employing two intermeshing helical screws that continuously compress air.

Industrial rotary screw compressors are categorized into two main categories: oil-injected and oil-free.

Oil-Injected Rotary Screw Air Compressor: These compressors use oil for lubrication and sealing, crucial for heavy-duty industrial applications. The oil helps cool the compressor, ensuring it runs efficiently under high stress.

Oil-Free Rotary Screw Air Compressor: Just like oil free reciprocating air compressors excel in applications demanding ultra-clean air, oil-free rotary screw compressors excel in situations where even trace amounts of oil contamination are unacceptable. These variants eliminate oil from the compression chamber, making them suitable for sensitive environments like pharmaceuticals or electronics. They provide contaminant-free compressed air for critical applications.

Bimpex is one of the leading air compressors distributor, which provides a wide range of industrial screw air compressors that offer numerous features and benefits. Let us take a look at some of the compelling reasons why these air compressors are the optimal choice for your business.

Low Noise: Designed with noise-dampening technology, it makes the compressor operate quietly and efficiently. Additionally, they are compact in size, making it convenient to store them anywhere and providing a quiet and safe working environment.

Low Maintenance: These compressors require less maintenance than reciprocating compressors because of the simple design and fewer moving parts, some compressors even have 70% of less moving parts making them durable and reduces downtime.

Energy Efficiency: Industrial screw air compressors are designed for energy efficiency, resulting in lower operating costs and reduced environmental impact.

High Volume Air Output: Industrial screw air compressors can produce a high volume of compressed air, making them suitable for a variety of industrial applications.

Automated Controls: Many industrial screw air compressors come equipped with automated controls, allowing for easy operation and monitoring.

Improved Air Quality: Industrial screw air compressors provide cleaner and drier compressed air, which is essential for certain industrial applications.

Bimpexs screw air compressor has a variety of industrial applications due to its efficiency and reliability. Here are some examples of how it can be used in various industries:

Food and Beverage: Air compressors for food and beverage industry are used in the food and beverage industry for tasks such as packaging, bottling, and labeling, as well as providing compressed air for food processing and preservation.

Iron and steel Industry: They are significantly used in the iron and steel industries for driving the lubrication system, positioning material trucks, drilling the slag chamber, and deaerating gas. In industrial boilers, they also aid in preserving stable combustion conditions.

Manufacturing Industry: In the manufacturing industry, screw air compressors are frequently used to power pneumatic tools like drills, grinders, and sanders. They are used to drive air-powered equipment like conveyor systems and production lines.

Pet Bottling Industry: Air compressors for pet bottling industry has varied application such as in providing compressed air for blowing, filling, labeling, and packaging processes. They can also supply compressed air for cleaning and drying the bottles and the production lines.

Medical Industry: In the medical industry, screw air compressors are utilized to provide power to medical equipment and devices, including ventilators and dental tools.

Automotive Industry: Screw air compressors for automotive industry are utilized in the automotive industry to provide compressed air for assembly lines, power pneumatic tools, and assist in painting processes.

Textile Industry: Screw air compressors for textile industry are used to power equipment and machines used for weaving and knitting. They are also used for dyeing, printing, and finishing processes. Compressed air is also used for cleaning and conveying textile materials during production.

Glass Industry: Screw air compressors for glass industry are used to power pneumatic tools such as glass cutters, to provide compressed air for glass blowing, and to operate various glass polishing and grinding machines.

Iron and Steel Industry: Screw air compressors are used in the iron and steel industry for a variety of tasks such as powering pneumatic tools, driving the lubrication system, positioning material trucks, drilling the slag chamber, and deaerating gas. They also aid in maintaining stable combustion conditions in industrial boilers.

Shipping Industry: Air Compressors for shipping industry are used for supplying compressed air to pneumatic tools, powering hydraulic systems, and controlling ship engines. They are also used for cleaning and painting ships, as well as for providing air for breathing apparatus and firefighting equipment.

Bimpex being the leading rotary screw air compressors dealer in Mumbai offers an extensive collection of air compressors. So, if you are interested in investing in premium industrial air compressors, do not hesitate to get in touch with us. We can help you find the right air compressor for your industrial needs.

The cost of rotary screw air compressors varies significantly based on factors like capacity, HP and features. On average, smaller models can range from ₹ 50K to ₹ 3.5 Lakh, while larger industrial-grade compressors can range from ₹ 4 lakh to ₹ 35 lakh or more, depending on specifications. It’s advisable to request quotes directly from suppliers for accurate pricing.

Operating oil-lubricated screw compressors involves safety measures. Regularly inspect oil levels, ensuring they aren’t too high or low. Follow maintenance schedules to prevent oil contamination. Maintain proper ventilation to avoid oil mist inhalation. Wear appropriate protective gear and follow manufacturer guidelines for safe operation. Conduct training sessions to educate personnel on safety protocols.

For optimal performance, screw-type air compressors need routine maintenance. This includes regular oil changes, air filter inspections, and cleaning to prevent buildup. Check for leaks, maintain appropriate oil levels, and adhere to service schedules. Regularly monitor pressure and temperature gauges. Lubricate moving parts, inspect belts, and conduct thorough system checks to ensure efficient operation and extend the compressor’s lifespan.

A screw element compressor is a type of positive displacement compressor. It operates on a rotary principle, utilizing two helical screws—rotors—intermeshed to compress air. As the screws rotate, air gets trapped, gradually reducing the space and increasing pressure. This efficient mechanism delivers a continuous flow of compressed air, offering high performance and reliability in various industrial applications.

Copyright © 2025 All Rights Reserved

WhatsApp us