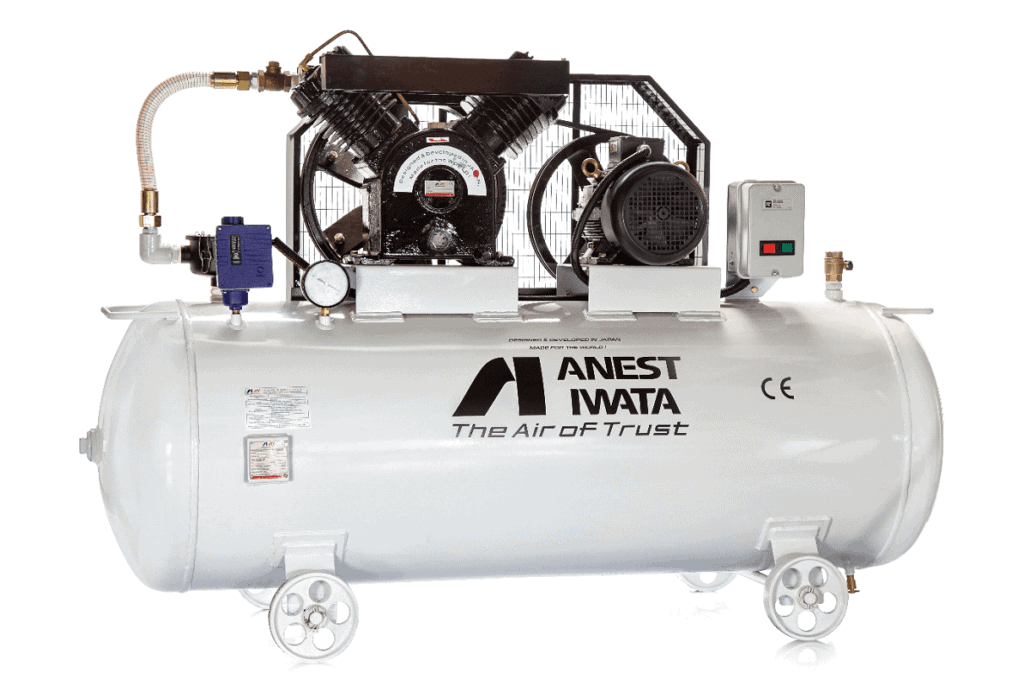

Bimpex offers a range of Industrial vacuum pumps that are used to create a vacuum environment within various systems, including containers, tubes, and pipes. This process eliminates gases or liquids from the enclosed spaces, leading to low-pressure levels within the system.

Our Vacuum pumps are designed to meet the requirements of large-scale manufacturing, delivering robust performance, and ensuring the removal of unwanted gases or vapors from processing environments. They have a wide variety of applications such as in food, pharmaceutical, chemical, and many more such industries, making them an indispensable tool for optimizing production processes and enhancing overall industrial efficiency.

As the foremost vacuum pump distributor, Bimpex offers premium vacuum pumps made from durable materials, which ensures their endurance during the continuous harsh environment across various industries.

As a leading industrial vacuum pump supplier in Mumbai, India, Bimpex offers a wide range of reliable and high-quality vacuum pumps. In this section, we will discuss the key features and benefits of the Bimpex industrial vacuum pump that set it apart from its competitors.

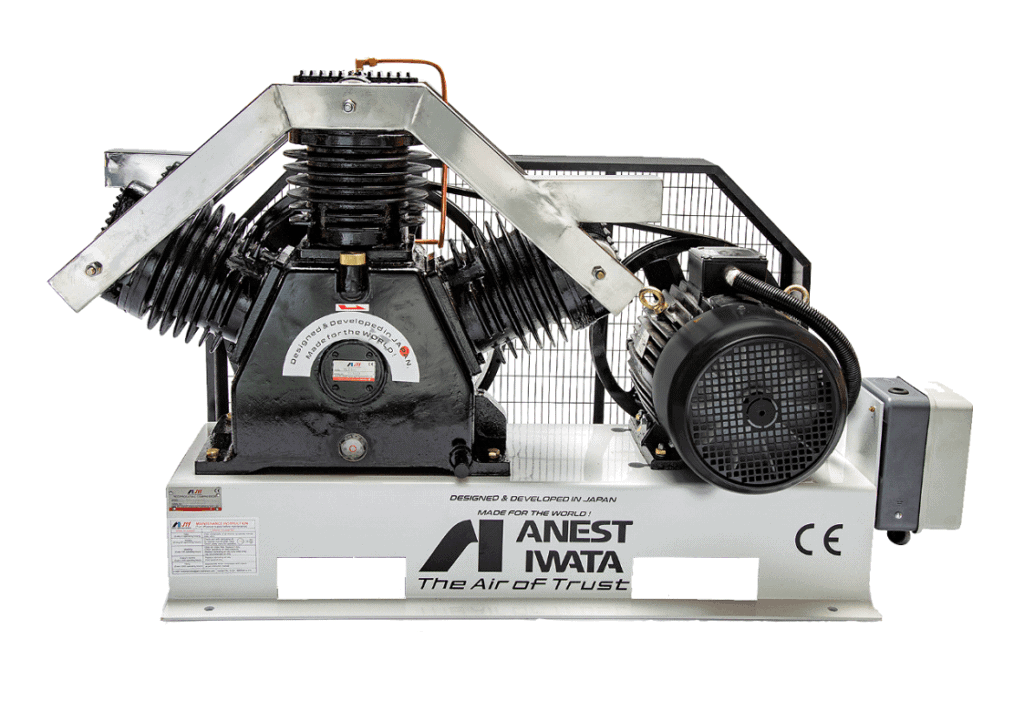

Durability: Since these pumps are made of heavy-duty stainless steel material it allows them to withstand tough conditions, including high temperatures, corrosive materials, and continuous use.

Low operating costs: Designed for easy operation and maintenance, these industrial vacuum pumps offer reliable performance at low operating costs for years to come.

High Efficiency: Bimpex’s vacuum pumps efficiently remove unwanted gases and liquids, reducing process duration and increasing output, improving manufacturing efficiency. They also offer power-saving benefits and help reduce the overall carbon footprint of the manufacturing process.

Low Oil Carry Over: Our industrial vacuum pumps are designed with low oil carryover features, which minimize the amount of oil that is carried over into the vacuum. These features may include specially designed exhaust systems, high-quality filtration systems, and other mechanisms that help separate the oil from the gas or vapour being pumped.

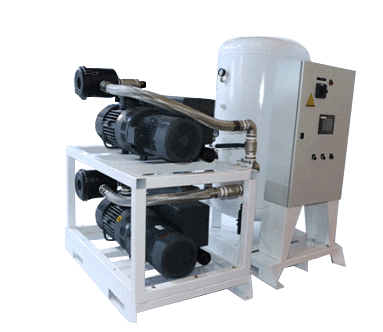

Bimpex, a leading industrial vacuum pump dealer in Mumbai, offers versatile vacuum pumps that have applications across leading industries. From hospitals and healthcare to the plastic and composite industry, these pumps play a critical role in ensuring the efficient and safe operation of many industrial processes.

Hospitals: Vacuum pumps are used for suctioning fluids and gases during medical procedures in hospitals.

Laboratories: Our vacuum pumps are utilized for filtering and removing contaminants from samples and equipment in laboratories.

Food and Beverage: In the food industry, Bimpex’s vacuum pumps are used for processing tasks such as vacuum packaging, removing air, and preserving the freshness of food products. It is also used for degassing and removing air from liquids such as wine.

Packaging: Pumps are used for vacuum sealing packages, to ensure that there’s no excess air that could spoil the package content such as dairy, foods & beverages.

Dentals: Dentists use vacuum pumps during dental procedures to suction out saliva and fluids that can interfere with the procedure.

Paper & Printing: Our industrial vacuum pumps are used by the printing and paper industry for removing air bubbles and excess moisture from paper and printing materials.

Wood Industry: They are used to remove sawdust and other debris from wood processing machinery.

Solar and Energy Industry: Bimpex’s vacuum pumps are used for degassing and removing impurities from solar panels and other energy-related components.

Glass Industry: Our vacuum pumps can be used during the production of glass, to remove air bubbles and excess moisture for high-quality glass production.

Environmental Engineering: Vacuum pumps are used to remove contaminants from soil and water samples collected for environmental engineering applications such as groundwater remediation, soil vapor extraction, and air sampling for pollutant analysis.

Chemical and Pharmaceutical Industry: Vacuum pumps are commonly used for filtering and removing contaminants from chemical and pharmaceutical products.

Plastic and Composite Industry: The industry uses vacuum pumps to remove air and impurities from plastic and composite materials during manufacturing processes.

Vacuum pumps should be maintained regularly to ensure optimal performance and prevent breakdowns. The frequency of maintenance depends on the type and usage of the pump.

The price of an industrial vacuum pump depends on various factors such as the pump’s capacity, features, and application requirements. To get an accurate quote and find the right vacuum pump for your needs, we encourage you to contact our team of experts.

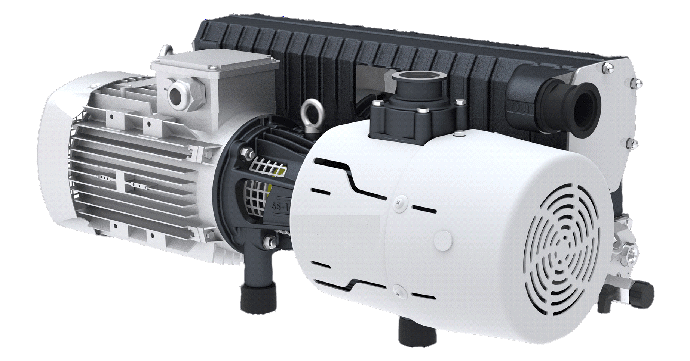

An industrial vacuum pump operates by creating a low-pressure or vacuum environment, which allows the air or other gases to be removed from a system or container, creating a partial vacuum. As the pressure decreases, the gas expands until it is finally removed by the pump. The process is repeated until the desired level of vacuum is achieved. So, it’s not that the pump compresses the air or gas, but rather it removes it to create a vacuum.

It is not advised to use just any oil for your industrial vacuum pump. It is always suggested that one refers to the manufacturers’ guidelines to ensure that the correct type of oil is used. Going through these specifications helps in ensuring optimal pump operation.

Below are the specifics that can help you enhance your vacuum pump’s performance:

Vibrating vacuum pumps can be a result of inadequate lubrication, imbalance, misalignment, or worn components. If your vacuum pump is vibrating or making abnormal noises inspect it for any irregularities, ensure proper alignment and foundation, and address worn parts. If everything seems okay, check if the pump is operating within the specified parameters by the manufacturer.

Worn bearings, misalignments, cavitation, and improper lubrication of the vacuum pump can make it noisy, while in operation. To maintain the longevity of the pump it is advised that this concern is properly addressed. Regular maintenance, proper lubrication, and following operation limits set by the manufacturer will help you to minimize noise.

Overheating in the vacuum pump is the result of factors such as improper lubrication, faulty cooling systems, and high ambient temperatures. It is essential to address these issues as it will help you to tackle overheating and prevent damage to the pump.

A vacuum pump may fail to reach ultimate pressure due to one or more of the following reasons:

A proper inspection and maintenance to repair these faults will help you to achieve te optimum pressure. Also, take time to ensure the system gets a regular oil change and its operation is as per the manufacturer specifications for optimal performance.

To prevent oil leaks in your vacuum pump, check for worn or damaged seals, tighten connections, and ensure proper sealing. Regularly inspect and replace worn components, and adhere to the manufacturer’s guidelines for correct oil type and maintenance procedures to minimize oil leakage.

Copyright © 2025 All Rights Reserved

WhatsApp us